The Chinese electric vehicle manufacturer BYD has experienced a significant surge in its quarterly revenues, surpassing Tesla for the first time.

It reported revenues exceeding 200 billion yuan ($28.2 billion, £21.8 billion) from July to September. This represents a 24% increase compared to the same timeframe last year and outpaces Tesla’s quarterly revenue of $25.2 billion.

Nevertheless, Tesla managed to sell more electric vehicles (EVs) than BYD during the third quarter.

This development coincides with rising EV sales in China, bolstered by government subsidies aimed at encouraging consumers to replace their gasoline-powered vehicles with electric or hybrid models.

In addition, BYD achieved a monthly sales record in the last month of the quarter, indicating a continued upward trend for China’s leading car manufacturer.

However, there is an increasing backlash overseas against the Chinese government’s backing of local car manufacturers like BYD.

Recently, the European Union implemented tariffs of up to 45.3% on imports of electric vehicles made in China throughout the bloc.

Chinese EV producers were already subject to a 100% tax in the United States and Canada.

These tariffs aim to address alleged unfair government subsidies for China’s automotive industry.

As of last week, official figures revealed that 1.57 million applications had been submitted for a national subsidy of $2,800 for each older vehicle exchanged for a more environmentally friendly one.

This is in addition to other existing government incentives.

China is relying on high-tech products to rejuvenate its struggling economy, with the EU representing the largest international market for the country’s electric vehicle sector.

Over the past two decades, the domestic car industry in China has expanded rapidly, and brands like BYD have begun to enter international markets, alarming the EU, which fears that local companies will struggle to compete with lower pricing.

Analysts are confident that this year will belong to Chinese brands, which are growing at a pace faster than that of Elon Musk’s company.

A few years back, it was believed that Volkswagen was the only potential challenger to Tesla’s dominance in electric vehicle sales. However, since 2022, BYD has been posing a significant threat to the American firm. The Chinese automaker exhibits a remarkably high growth rate, surpassing that of Tesla, and the two companies are now in close competition.

Indeed, BYD had already outperformed Tesla in the fourth quarter of 2023, but Elon Musk’s company retained its top position by summing up the total number of cars sold over the entire year. What will transpire in 2024? Let’s explore further.

A different kind of growth

Tesla experienced a sluggish first quarter in 2024, but in the second quarter, recent data suggests that it regained traction and experienced growth, exceeding Wall Street’s predictions. BYD, on the other hand, had a similar experience, though it slightly missed expectations.

From April to June, electric vehicle sales reached 443,956 for Tesla and 426,039 for BYD. While BYD has some ground to make up, analysts anticipate that the Chinese brand will surpass Tesla by year’s end.

Examining the figures for the year’s initial months, Tesla delivered 813,739 units, whereas BYD delivered 726,153. Compared to the same period in 2023, these changes amount to -9% for Tesla (which sold nearly 890,000 cars last year) and +18% for BYD (which delivered just under 600,000).

Tesla: 813,739 vehicles sold in the first half of 2024 (-9% compared to 2023)

BYD: 726,153 vehicles sold in the first half of 2024 (+18% compared to 2023).

China, increasingly the leader

In comparison to the first quarter of this year, growth stood at 19% for the American company and 42% for the Chinese company. It is specifically this varying rate of growth, fueled by BYD’s more diverse range that includes affordable models, that has led many analysts, including those at Counterpoint, to speculate about an eventual takeover.

There is a second factor at play. China (where BYD is naturally well established) continues to be the foremost market for electric vehicles. This will aid all Chinese brands in their expansion, as BEV sales in that region are projected to be four times higher than in North America this year. Moving forward, it is anticipated that the Land of the Dragon will capture a 50% market share (by 2027) and surpass both Europe and North America combined before the decade concludes.

In 2011, Elon Musk mocked BYD during a Bloomberg interview, laughing at their products.

“Have you seen their car?” Musk remarked. “I don’t find it particularly appealing, the technology isn’t very impressive. Additionally, BYD faces significant challenges in its home market of China. They should primarily focus on ensuring their survival in China.”

BYD, however, did not go under. Instead, it overtook Tesla in the fourth quarter to become the leading EV manufacturer, selling more electric vehicles than its U.S. competitor.

“Their ambition was to become the largest auto manufacturer in China and establish the country’s manufacturing reputation,” said Taylor Ogan, CEO of Snow Bull Capital, regarding BYD’s long-term goals.

So, what led the Chinese firm, which started by producing phone batteries, to evolve into a major electric vehicle manufacturer?

The history of BYD

Although BYD is now recognized as a giant in electric vehicles, its influence extends into various sectors including batteries, mining, and semiconductors, which significantly contributes to its success.

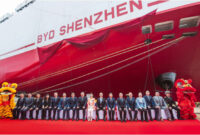

Founded in 1995 by chemist Wang Chuanfu in Shenzhen, a crucial tech hub in southern China, BYD started with 20 employees and 2.5 million Chinese yuan in initial funding, equivalent to about $351,994 today.

The company ventured into lithium-ion battery production in 1996, coinciding with the rise in mobile phone usage. By 2000 and 2002, BYD was supplying its batteries to major mobile phone brands Motorola and Nokia.

In 2002, BYD was listed on the Hong Kong Stock Exchange, taking advantage of its success in the lithium-ion battery sector.

BYD’s transition to automobiles

BYD’s acquisition of a small car manufacturer named Xi’an Qinchuan Automobile took place in 2003.

Two years later, it released its inaugural vehicle, the F3, a traditional combustion engine model. In 2008, it introduced the F3DM, its initial venture into electric vehicles, which was a plug-in hybrid.

That same year, Warren Buffett’s Berkshire Hathaway made a $230 million investment in BYD, which significantly boosted its electric vehicle goals.

BYD kept pushing into the electric vehicle market, leveraging its experience as a battery manufacturer. In 2020, the company rolled out the Blade battery, which many credited for BYD’s rapid growth in the EV sector.

This LFP (lithium iron phosphate) battery gained attention during a time when many battery producers were moving away from LFPs due to assumptions about their inferior energy density; specifically, that they were too heavy for the energy they could store.

However, BYD promoted the Blade as a revolutionary battery that provided excellent energy density while ensuring high safety levels. It decided to feature this battery in its Han sedan, launched in 2020, which was aimed at competing with Tesla’s Model S. Subsequently, BYD included the Blade in its later models.

“The energy density at both the cell and pack levels exceeded BYD’s initial projections… It was a remarkable surprise,” Ogan commented.

In 2020, BYD sold 130,970 pure battery electric vehicles. Last year, its sales skyrocketed to 1.57 million battery-powered vehicles.

What contributed to BYD’s success?

The achievement with the Blade highlights the reasons behind BYD’s success in electric vehicles, which include strategic investments and the diversification of its business beyond just automobiles.

“BYD gained significant experience as a supplier in the high-tech industry, building resilience by providing batteries to demanding clients like Apple,” Tu Le of Sino Auto Insights explained to CNBC.

“Wang Chuanfu possessed the foresight to acquire a struggling local automotive brand, allowing him to innovate in battery technology, enabling the company to sell to other automakers. To top it off, they were diligently focused on continually enhancing the design, engineering, and quality of its own vehicles. Little did we realize that everything they had accomplished over the past 15 to 20 years prepared them to surpass Tesla in Q4 ’23.”

Initially, BYD didn’t dive straight into fully electric vehicles. The company continued to market hybrid cars, which, according to Alvin Liu, an analyst at Canalys, was critical for BYD’s early success.

“During the initial phase of the Chinese electric vehicle market, BYD opted to launch both Battery Electric Vehicles (BEV) and Plug-in Hybrid Electric Vehicles (PHEV) simultaneously. This approach enabled BYD to capture the market when charging infrastructure was poorly developed, and consumers were uncertain about the benefits of electric vehicles,” Liu stated to CNBC.

“The PHEVs’ features, including high economic efficiency and the absence of range anxiety, played a vital role in helping BYD dominate the market.”

Liu noted that BYD strategically positioned itself within the mid-range market, where competition was less intense in China, thus aiding its expansion. According to Liu, BYD has also excelled in branding by creating different sub-brands to address various price segments, with one example being BYD’s mid-to-high-end EV brand, Denza.

Beijing supports electric vehicles

In addition to BYD’s own strategies, its growth has been bolstered by significant backing from the Chinese government for the nation’s electric vehicle sector. In recent years, Beijing has provided subsidies to encourage the purchase of electric cars and has supported the industry. These initiatives began around 2009, coinciding with BYD’s effort to enhance its EV focus.

According to Rhodium Group, BYD received about $4.3 billion in government support between 2015 and 2020.

“BYD is a very innovative and versatile company, but its success is closely tied to the protection and support from Beijing,” stated Gregor Sebastian, a senior analyst at Rhodium, in an interview with CNBC. “Without the backing from Beijing, BYD would not have achieved its current status as a global leader.”

“Over time, the company has benefited from lower-than-market rates for equity and debt financing, enabling it to increase production and research and development efforts.”

Global aspirations

Having secured a dominant position in China’s EV market, BYD is now aggressively expanding internationally. It markets vehicles in several countries, including the United Arab Emirates, Thailand, and the UK.

In Southeast Asia, BYD holds a 43% share of the electric vehicle market. However, its global expansion strategy extends beyond simply selling cars; it also includes manufacturing and sourcing materials.

BYD announced in December its intention to launch its first manufacturing facility in Europe, located in Hungary. Additionally, the company is exploring opportunities to acquire lithium mining assets in Brazil, which is vital for BYD’s batteries.

Despite these global ambitions, the company faces increased government scrutiny regarding the subsidies enjoyed by Chinese automakers.

In September, the European Commission, which is the executive body of the European Union, initiated an investigation into the subsidies provided to electric vehicle manufacturers in China.

Simultaneously, the U.S. is seeking to strengthen its domestic electric vehicle industry through the Inflation Reduction Act, aiming to limit competition from Chinese firms.

“Measures like the IRA and the EU’s subsidy investigation are designed to slow China’s advancement in these markets,” remarked Sebastian from Rhodium.

“To maintain its growth trajectory, BYD is actively confronting these political challenges, as evidenced by its recent investment in an EV plant in Hungary, highlighting its dedication to global growth.”

What’s next?

The competition between Tesla and BYD — the two largest electric vehicle manufacturers in the world — is poised to persist. According to Le from Sino Auto Insights, he believes BYD has not yet achieved its “maximum potential.”

“Many automotive companies historically overlooked them, which echoes the early journey of Tesla when it was similarly underestimated,” Le noted.

On the other hand, Tesla is bracing for tougher competition in 2024, with Chinese rivals introducing more models and established automakers attempting to catch up in the electric vehicle landscape.

Daniel Roeska, a senior research analyst at Bernstein Research, mentioned to CNBC that Tesla doesn’t have a significant driver for sales volume in its vehicle lineup in the upcoming months. Conversely, BYD may experience more rapid growth.

“BYD, in contrast, is fully accelerating its efforts … by boosting growth in Europe and other international markets. Thus, there is considerable potential for growth in BYD’s narrative over the next 12 to 24 months,” Roeska stated.

Tesla’s Musk has admitted that he shouldn’t have underestimated BYD. In a post on X responding to a video of a 2011 Bloomberg interview, Musk remarked: “That was many years ago. Their vehicles are very competitive these days.”

BYD announces additional international growth

On July 16th, BYD revealed its intention to set up a facility in Cambodia, representing the newest phase in its global growth strategy. This Cambodian site will support the six other plants that have been announced outside of China, which are located in Brazil, Turkey, Thailand, Hungary, Indonesia, and Uzbekistan. BYD’s international growth is occurring during a period when several nations are looking to impose tariffs on vehicles imported from China to safeguard their domestic automotive sectors.

The Current Situation

Most of BYD’s vehicles are manufactured at its three factories in China: Shaanxi, Hunan, and Guangdong, which correspond to its largest customer base. In 2023, BYD sold 2.57 million of a total of 2.7 million vehicles in China. However, the company has faced challenges in increasing its market share outside of China, with its export growth not keeping pace with domestic sales. After China, the Asia Pacific region, which includes Thailand, Malaysia, and Australia, was its next largest customer base in 2023. BYD plans to double its vehicle exports in 2024 compared to 2023.

Southeast Asia

In recent years, Southeast Asia has become a center for electric vehicle production. BYD already operates a facility in Thailand with a capacity of 150,000 units annually. Furthermore, it has confirmed plans to create another plant in Indonesia, also with a capacity of 150,000 units, expected to start production in January 2026. The Cambodian plant will serve as an assembly facility capable of processing 20,000 units each year for local and export markets. Although the market share for electric vehicles in the region remains limited, it is on the rise. With three plants in Southeast Asia, BYD aims to tap into this developing market and utilize the region as a launching pad for exports worldwide.

Europe

BYD intends to set up an electric vehicle manufacturing facility in Hungary within the next three years and has announced another plant in Turkey, which is expected to be operational by the end of 2026. Each of these plants will have an annual capacity of 150,000 units. This expansion comes as Chinese electric vehicle manufacturers exporting to the EU and Turkey encounter increased tariffs. In 2023, BYD sold slightly over 15,000 vehicles in the EU, EFTA, and the UK, according to the Rho Motion EV & Battery Database. Within the first six months of 2024, it has already equaled that figure. Targeting Europe as a significant area for growth, BYD recently sponsored the UEFA European Football Championship to enhance its brand visibility in the region. Additionally, BYD gains an advantage from having the lowest tariff among all Chinese imported vehicles under the newly implemented EU tariffs.

South America

BYD’s factory in Brazil is currently being built and is slated to begin operations by late 2024 or early 2025, with a capacity of 150,000 units. While the company’s footprint in the region was limited in 2023, sales have surged dramatically in 2024. In the first half of 2024, BYD sales in Brazil soared by over 1,800% compared to the same period in 2023. Brazil has gradually increasing import tariffs on electric vehicles, reaching 35% by July 2026. The new facility will help alleviate the impact of these tariffs and broaden BYD’s presence in the region. Establishing a brand identity has also been a priority in this market, with the company recently sponsoring the CONMEBOL Copa América.

Uzbekistan

BYD’s facility in Uzbekistan commenced operations in January 2024, with a production capacity of 50,000 vehicles annually. Additionally, BYD is planning to form a joint venture with a local company, UzAuto. With this facility, BYD seeks to serve the expanding electric vehicle market in Central Asia.

Rho Motion’s Assessment

BYD stands as one of the few fully electric vehicle manufacturers capable of generating profits, with Tesla being another prominent competitor. This financial strength allows BYD to pursue global expansion more easily than other companies that operate at considerable financial losses. As many countries increase import tariffs on electric vehicles, BYD has proactively established facilities in Brazil, Hungary, and Turkey. Its factories in Southeast Asia will also act as key strategic locations for broader global expansion and export activities. Once all its facilities are operational, BYD will possess an annual global production and assembly capacity of 820,000 units outside of China, with potential for further expansion.

BYD’s global growth initiative faces significant challenges in Japan.

BYD is launching electric vehicle charging stations and increasing marketing efforts and customer incentives in Japan, seeking to enhance sales in a market that has posed difficulties for the Chinese automaker’s worldwide expansion.

Supported by Warren Buffett, BYD has become the largest manufacturer of electric vehicles in China following years of rapid growth domestically.

The company is now looking to expand internationally, including into Japan, which is among the largest automotive markets globally.

However, Japan presents a tough landscape for foreign car manufacturers.

The demand for electric vehicles has historically been low, and the government modified the calculation of EV subsidies this year, which reduced support for BYD and several competitors and raised fears of protectionism.

In order to attract Japanese consumers, BYD is providing discounts on the first 1,000 units of its latest model and airing TV ads featuring a Japanese actress.

This approach has resulted in marketing expenses that are higher than initially anticipated.

BYD’s efforts to expand internationally are under close observation, particularly as the company’s value is nearly equivalent to that of both GM and Ford combined.

Nonetheless, some Japanese consumers are hesitant about purchasing high-cost products from China due to concerns over quality.

The two largest economies in Asia also have a complex history marked by wartime events and ongoing political issues.

“The cars are impressive, but I doubt they’ll be successful in Japan,” remarked Yukihiro Obata, a 58-year-old who visited a BYD showroom in Yokohama near Tokyo with his son in July.

“Japanese consumers generally perceive domestically manufactured goods as superior to those from China and South Korea.

It’s hard for us to believe that Chinese products could be of higher quality,” he expressed.

Obata mentioned that he was open to the idea of buying a foreign vehicle and was also looking into EV options from Mercedes-Benz, Audi, and Hyundai.

BYD, based in Shenzhen, inaugurated its first showroom in Japan in February of last year, having sold over 2,500 vehicles to date.

In comparison, Toyota has sold slightly more than 4,200 battery electric vehicles in Japan during the same timeframe, while nearly 17,000 Teslas had been registered in the country as of the end of March 2023, according to the latest available industry data.

BYD currently offers three models and operates over 30 showrooms.

“There are individuals in Japan who genuinely dislike Chinese products, so it’s not wise to aggressively push our brand on them,” stated Atsuki Tofukuji, the president of BYD Auto Japan.

Instead, he aims to win over consumers by highlighting BYD’s affordability and performance.

ELECTRIC VEHICLE SUBSIDIES

Electric vehicles made up just over 1% of the 1.47 million passenger cars sold in Japan in the first seven months of this year, based on industry data.

This figure excludes the low-power “kei” mini cars designed for the domestic market.

Sales of electric vehicles have been slow in Japan because Toyota and other local manufacturers have prioritized hybrid technology.

In April, the government revised its EV subsidy program, stating it will encourage the development of charging infrastructure and other related amenities.

Subsidies, which were previously based on vehicle performance, now consider factors such as the number of fast chargers a manufacturer has installed and the quality of after-sales service.

The subsidy for BYD’s Atto 3 SUV, priced at 4.5 million yen ($30,996.00), was almost halved, dropping to 350,000 yen from 650,000 yen.

These reductions in subsidies have negatively impacted sales, according to Tofukuji during a company event in July.

In response, BYD offered 0% loans from April to June, along with cashback deals on home chargers during July and August.

The company also intends to install a fast charger in 100 locations by the end of the next year, as revealed by Tofukuji to Reuters, a plan that could potentially enable it to qualify for larger subsidies.

To boost its brand recognition, BYD began airing television commercials featuring Masami Nagasawa, a Japanese actress and model.

This strategy has attracted more customers, although the automaker has exceeded its originally planned marketing budget in Japan, as Tofukuji noted, without disclosing the specific marketing expenditure.

BYD’s lineup in Japan includes the Seal sedan, retailing for 5.28 million yen for the rear-wheel-drive model, which qualifies for a 450,000 yen subsidy.

Additionally, the company offers the Dolphin, starting from 3.63 million yen and eligible for a 350,000 yen subsidy.

JAPANESE APPROACH

The change in subsidies might demonstrate a governmental effort to protect the domestic automotive sector, suggested Zhou Jincheng, manager of China research at the auto research firm Fourin in Nagoya.

“They needed to implement some measures to safeguard their automotive industry,” Zhou stated.

An official from the industry ministry remarked that the goal of the revision was to create an environment that enables sustainable use of electric vehicles, promoted “in a Japanese manner.”

Other automakers that experienced subsidy reductions included Mercedes, Volkswagen, Peugeot, Volvo, Hyundai, and Japanese brand Subaru.

Nissan and Toyota’s SUVs continued to qualify for the maximum subsidy of 850,000 yen, and Tesla also witnessed equal or higher subsidies on the models it markets in Japan.

While overall electric vehicle sales are low, foreign automotive brands constituted nearly 70% of sales in the first seven months of the year.

The decreased subsidy did not deter Kyosuke Yamazaki, a first-time car buyer in his 30s, from purchasing a BYD Atto 3, although he lost around $2,000 in savings due to his purchase occurring after April. He mentioned that he preferred the longer driving range of these vehicles compared to Japanese competitors and was comfortable buying from a Chinese company. “I previously worked in Shanghai,” he noted. “I’m familiar with BYD.”

BYD recently declared a $1 billion investment in Turkey. This announcement quickly garnered attention: In July, the Chinese electric vehicle (EV) manufacturer BYD (Build Your Dreams) revealed plans to invest $1 billion in Turkey. In the western region, particularly in the industrial city of Manisa, BYD aims to establish a manufacturing facility with the capacity to produce 150,000 electric and hybrid vehicles. Furthermore, BYD also intends to set up a research and development center near Izmir.

Choosing Turkey represents an industrial policy achievement for Turkey’s president, Recep Tayyip Erdoğan. Additionally, it further solidifies the strengthening economic collaboration and logistical ties between Ankara and Beijing.

BYD’s investment marks its entry into the Turkish market, which has significant implications for European competitors in the industry and the European Commission in Brussels. Turkey’s customs union with the European Union (EU) plays a crucial role in BYD’s manufacturing and export capabilities. Since automobiles will be produced in Turkey, BYD can enhance its supply chains in Europe without incurring additional customs duties on Chinese EVs that were introduced by the Commission in July 2024. Through this strategic approach of “tariff jumping,” BYD gains pricing benefits in EU markets.

Selecting Turkey for a new EV manufacturing facility acknowledges the evolving production capacities of the Turkish automotive sector. Chinese firms like BYD are capitalizing on the industry’s increasing export capabilities. In recent years, the sector has developed its innovation ecosystem with the production of Turkey’s first domestic EV, the Togg.

It is also important to note that BYD’s decision to invest in Turkey included a significant incentive. The Turkish government suspended import taxes totaling 40 percent (added to the purchase price) for EVs from China. This measure to eliminate tariffs aims to attract manufacturers like BYD to invest and produce in Turkey, yielding positive outcomes for both parties. Ankara has utilized its leverage because BYD now avoids Turkish taxes and future EU tariffs.

The Sino-Turkish agreement has another significant aspect: the joint venture is being embraced across Turkey’s political spectrum. Given the current political divisions in Turkey, this is noteworthy. It highlights the importance of the bilateral agreement, which represents the largest single Chinese foreign direct investment in Turkey in the past decade. BYD’s commitment is expected to boost the Turkish automotive supply chain and bring about a technological advantage in the nation’s manufacturing sectors.

The implications of this decision extend globally, presenting challenges for Europe. For BYD, establishing operations in Turkey will create a value-added network for electric mobility while facilitating the import of essential materials for battery production and, ultimately, the assembly of various EV models in BYD’s expanding portfolio.

The joint venture paves the way for European export markets and opens access to regions in the Middle East, neighboring Turkic countries, and across Africa. Overall, BYD’s initiative in Turkey transcends a mere regional manufacturing effort; it strengthens the global growth strategy of the Chinese EV manufacturer.

This development raises concerns about the EU’s response to such challenges. Beyond focusing on Turkey, BYD’s European expansion includes Hungary, an EU member state where a second EV production facility is under construction. Chinese EV industry investments in countries like Turkey and Hungary are based on strategic considerations, as both countries maintain stable relations with China absent from trade disputes and potential sanctions.

BYD’s investments demonstrate how Chinese EV manufacturers are devising strategies to navigate around protectionist policies. Turkey serves as a crucial link in this strategy. The evolution of EV mobility is increasingly influenced at the intersection of East and West, with Turkey playing a pivotal role in connecting the two.

By avoiding EU tariffs on Chinese EVs, BYD positions itself for profitable sales within the Single Market. In light of this scenario, the EU must reassess its trade policies concerning non-EU nations. Consequently, the ongoing discussions about modernizing the customs union with Turkey should be given increased urgency and significance. Expanding the customs union should also address aspects such as supply chain transparency and updated subsidy regulations.

According to a post shared on X, Turkey’s industry minister, Mehmet Fatih, announced that production at the factory is set to begin by late 2026. This development is expected to enhance BYD’s capacity for manufacturing vehicles in Europe, with an estimated annual production capability of 150,000 vehicles.

BYD’s new manufacturing facility in Turkey reflects its strategic initiative to navigate the European Union’s recent restrictions on electric vehicle imports from China. Since Turkey is part of the EU Customs Union, vehicles produced there could potentially avoid the additional 17.4% tariff that Chinese electric vehicles must pay to enter the European market, as reported by Yahoo News.

In light of global trade tensions, BYD’s thoughtful choice highlights the hurdles that Chinese electric vehicle manufacturers have to face. The attempts by Western countries to shield their domestic automotive industries from cheaper Chinese imports have prompted BYD and its competitors to explore local production alternatives to circumvent stringent trade regulations.

Concerns from U.S. officials arise regarding possible market access loopholes stemming from the ambitions of Chinese electric vehicle brands, including BYD, MG, and Chery, to expand their reach into countries like Mexico. These developments underscore the delicate balance these companies must maintain while pursuing international growth and complying with evolving trade regulations.

Philip Nothard, Director of Insight and Strategy at Cox Automotive, noted that BYD’s strategic investments in Turkey represent the company’s aspirations for global and European growth. While tariffs present challenges, he emphasized that organizations like BYD are adept at adjusting their strategies to swiftly overcome regulatory hurdles.

BYD’s increasing footprint in the market poses a competitive threat to Tesla, which is a major player in the electric vehicle sector with a strong foothold in Europe. The EU’s crackdown on imports from China also affects Tesla’s operations in Europe, particularly regarding its gigafactory in Germany. This situation could lead to higher prices for some Tesla models, including the Model 3, in that region.

Coverage of BYD’s investment decision is predominantly framed in Western media within the context of new trade barriers in the U.S. and the EU. From the Chinese viewpoint, this correlation is relatively minor. BYD is rapidly establishing new vehicle manufacturing plants globally, not limited to Europe alone.

Just prior to the signing in Istanbul on July 4, BYD commenced operations at its latest factory located in Rayong, Thailand. Additionally, a BYD subsidiary is currently working on a new car battery production facility in Thailand. Earlier this year, BYD began production at a new factory in Uzbekistan. In Brazil, BYD has acquired a former Ford manufacturing site, while in Mexico, it is reportedly searching for an appropriate location.

The impressive developments illustrate that the Chinese automaker remains largely unaffected by the protectionist tendencies found in certain regions or nations, as noted by the Chinese specialist portal “CN EV POST.” This approach to “Go-Global” expansion by BYD is backed by strong and sustained market success. In the second quarter of 2024 alone, the electric vehicle manufacturer recorded sales exceeding 980,000 cars, marking a 40% increase compared to the same period the previous year, according to Bloomberg. Last year, BYD surpassed Tesla to become the market leader for electric vehicles in China and is now selling more vehicles across all powertrains than Volkswagen, the former local leader.

Analysts predict that the Shenzhen-based private company can maintain this successful trend in the forthcoming years. “We believe that other firms within the industry will struggle to match the company’s leadership in technology, which is built on a decade of innovation and exceptional vertical integration capabilities,” stated market analysts at HSBC regarding BYD.

The Chinese firm pursues a long-term strategy to manufacture as many of its core components in-house – from batteries to chips and electric drive systems. Accordingly, the company is significantly boosting its research and development efforts. BYD is investing one billion euros to establish a new vehicle factory in Turkey, which will have a production capacity of 150,000 vehicles annually. Simultaneously, a new research and development center is being planned, as stated by the Turkish Ministry of Industry.

While the additional tariffs imposed by Brussels on Chinese electric vehicles may have had a slight impact on BYD’s decision for its new location, it is important to note that Turkey is not an EU member. However, it does have a customs agreement with the EU and has free trade arrangements with 23 European nations.

BYD aims to strengthen its presence in the European market through operations in Turkey. The new facility is designed to enhance the company’s “logistical efficiency” to facilitate access to customers in Europe, as stated in BYD’s press release following the contract signing in Istanbul.

Turkey has increased import taxes on vehicles from China. Nevertheless, BYD is also focusing on the Turkish market, which has a population of nearly 90 million and a current electric vehicle penetration rate of 7.5 percent, presenting substantial potential. Like the EU, Turkey has recently sought to protect its domestic automotive sector from competition from China. In June, the Turkish government established an additional 40 percent import tax on cars from China, on top of the existing ten percent duty.

In July, these new additional taxes were revoked by a decree from President Erdogan for all Chinese firms that invest in Turkey. According to Bloomberg, this decree was signed shortly after Erdogan’s meeting with Xi Jinping, China’s state and party leader, at a conference in Astana, Kazakhstan.

Discussions about various tariff barriers in the USA, the EU, and Turkey should not overshadow the fact that BYD is actively positioning itself in the global market.

Originally, a particular property in Manisa province in Turkey was designated for a Turkish VW factory, which adds symbolic weight to this context. VW is facing declining capacities, and its plans for Turkey were abandoned in 2020. Meanwhile, Chinese manufacturers will now contribute to the vibrant automotive sector in Turkey, where companies like Fiat, Renault, Ford, Toyota, and Hyundai already have manufacturing facilities.

As a result of BYD’s decision, Turkey will gain 5,000 new jobs.

BYD aims to grow alongside Western partners. The automotive company intends to establish its presence in the global market through collaborations, with Uber and the supplier Forvia expected to play significant roles.

BYD is set on global expansion and is banking on partnerships to achieve this goal. The leading electric vehicle manufacturer in China has recently inked a deal with Uber to deploy 100,000 of its electric vehicles across multiple continents. Additionally, BYD will work with Forvia at its newly planned factory in Hungary, which is under construction.

Through its partnership with Uber, BYD plans to supply 100,000 electric vehicles to Uber drivers at reduced prices over the coming years, beginning in Europe and Latin America, and eventually expanding to the Middle East, Canada, Australia, and New Zealand. This initiative is anticipated to hasten the electrification of Uber’s global fleet, according to a press release from Uber.

BYD is collaborating with established names in the industry. Notably absent in the deal between the American ride-sharing service and China’s top EV manufacturer is the USA, where recent punitive tariffs on Chinese electric vehicles are exceptionally high.

For BYD, the partnership with Uber serves mainly as a marketing achievement. The Shenzhen-based car manufacturer recognizes the necessity of building its brand awareness beyond the industry in Europe and other international markets. To support this, the OEM entered into a contract with the German car rental company Sixt in 2022 for another 100,000 electric vehicles over a six-year period.

However, Sixt had to alter its strategy after the residual values of electric cars plummeted significantly in the first quarter of this year. It remains unclear whether this trend has affected Sixt’s enthusiasm for acquiring more electric cars from China.

In any case, BYD can benefit from any favorable news that bolsters its global market ambitions. For this reason, the company has also invested significantly in sponsorships for the European Football Championship and the “Copa America.”

Regarding the arrangement with Uber, Stella Li, CEO of BYD Americas, expressed her eagerness to see “our advanced electric cars soon becoming a common sight on the streets of many cities worldwide.” To realize this vision, despite the duty increase on imports of Chinese electric vehicles to 100 percent in the USA and over 27 percent in the EU for BYD, the manufacturer is currently planning or launching multiple factories, including ones in Brazil, Thailand, Turkey, and Hungary.

For the new European factory, BYD has formed a partnership with Forvia, wherein the French supplier will manufacture and operate the facility. This collaboration represents “an important milestone for both companies as we bring our partnership to Europe.”

Forvia and BYD have collaborated since 2017 through several joint ventures in various nations. One notable example is the joint venture “Shenzhen Faurecia Automotive Parts,” where Forvia holds a majority stake. Additionally, they operate several factories in China that produce car seats, electronics, interiors, and software for BYD. Recently, both companies inaugurated a new seat assembly facility in Rayong, Thailand.

During the launch of the new collaboration in Thailand, Patrick Koller, CEO of Forvia, expressed, “We are confident that this expansion will drive joint growth in the European market,” while also announcing new partnership initiatives in Hungary.

In this instance, both parties are optimistic about potential synergies. Forvia aims to counteract the decline in revenue from reduced deliveries to European car manufacturers by leveraging the success of its Chinese partner. Meanwhile, BYD expects Forvia to not only manufacture seats but also assist its entry into the European market through its established experience and industrial connections.

Forvia: emerging from a challenging phase with Chinese partners.

Recently, Forvia released its financial results for the first half of 2024 and downgraded its sales and margin projections. The company noted minimal growth in automotive production across Europe in the first six months of this year, attributing this to “the slowdown in the pace of electrification in Europe,” as explained by the Tier-1 supplier formed from the merger of Faurecia and Hella.

Forvia and Uber are optimistic about fostering successful electrification within the global automotive sector. They are placing their hopes on BYD, a frontrunner in the Chinese market. Should their strategy succeed, it could lead to a significant reshuffling of the current dynamics.

BYD’s choice to establish its new factory in Turkey is motivated by a number of strategic benefits. Turkey’s strategic location at the junction of Europe, Asia, and the Middle East offers BYD a logistical edge, making it easier to distribute products and access various markets. Furthermore, Turkey’s customs union with the European Union permits vehicles manufactured in Turkey to enter the EU market without the extra tariffs that apply to cars made in China. This is especially important given the recent EU decision to enforce tariffs reaching up to 38% on electric vehicles from China, a challenge that BYD has sidestepped by setting up production in a customs union member country.

The Manisa province, where the factory will be located, has traditionally been an automotive manufacturing center. Well-known car manufacturers such as Fiat, Renault, Ford, Toyota, and Hyundai have set up production facilities in the area, taking advantage of its strategic positioning and favorable business conditions. BYD’s new factory will join these international corporations, further strengthening Turkey’s role as a significant player in the global automotive sector.

The creation of BYD’s new facility in Turkey is anticipated to bring considerable economic advantages to the local economy. The factory is expected to generate roughly 5,000 direct jobs, offering employment possibilities and aiding in the region’s economic progress. In addition, the investment in local research and development centers will enhance Turkey’s skills in advanced automotive technologies, promoting innovation and growth in the industry.

The local supply chain is also poised to benefit from BYD’s establishment. The factory will likely ignite the growth of related sectors, generating indirect job opportunities and stimulating overall economic activity in the area. This investment is in line with Turkey’s broader economic objectives of attracting foreign direct investment and expanding its industrial sector.

Addressing EU Tariff Challenges Through Strategic Production Placement

One of the main reasons BYD opted to construct a facility in Turkey is to lessen the repercussions of the newly imposed EU tariffs on electric vehicles from China. The European Union’s decision to impose tariffs as high as 38% on Chinese-produced electric vehicles poses a significant obstacle for Chinese manufacturers. However, by manufacturing vehicles in Turkey, BYD can avoid these tariffs and sustain competitive pricing in the European market.

BYD contends with a tariff rate of 17.4% compared to its rivals, but establishing a production site in Turkey offers a long-term resolution to this issue. This strategy not only allows BYD to evade the tariffs but also positions the company advantageously in the European market, where the demand for electric vehicles is increasing due to stricter environmental regulations and consumer preferences for eco-friendly transportation options.

Future Outlook and Industry Impact of BYD’s Turkey Factory

BYD’s expansion into Turkey is part of its broader plan to establish a worldwide presence and become a leading figure in the electric vehicle sector. With recent openings in Thailand and future plans in Brazil and Mexico, BYD is swiftly creating a network of manufacturing bases in vital regions around the globe. This global growth is set to significantly boost BYD’s market share and reinforce its status as a frontrunner in the electric vehicle industry.

The new facility in Turkey is expected to manufacture between 20,000 and 25,000 vehicles for the Turkish market and export about 75,000 vehicles to the EU each year. This production capacity will assist BYD in addressing the escalating demand for electric vehicles in Europe and contribute to the region’s shift towards sustainable transportation solutions.

BYD’s presence in Turkey also has wider implications for the European automotive market. European car manufacturers will need to adjust to the heightened competition from Chinese electric vehicle producers and possibly reassess their strategies to preserve their market share. BYD’s entry into the European market via Turkey may also encourage other Chinese manufacturers to explore similar strategies, further heightening competition within the electric vehicle sector.

BYD’s investment of $1 billion in a new facility in Turkey signifies an important milestone in the company’s global expansion efforts. By leveraging Turkey’s strategic geography and customs union with the EU, BYD aims to bolster its position in the European market and manage the challenges posed by the recent EU tariffs on Chinese electric vehicles. The new plant will not only yield considerable economic advantages for the area but will also strategically position BYD in the competitive European automotive landscape. As BYD continues its global expansion, its presence in Turkey is expected to be pivotal in its quest to become a leading player in the electric vehicle market.